Weatherford Com CAM15-160 Bucking Unit

The Comfort Bucking Systems ComCAM by Weatherford is the perfect system for all pipe facilities. Semi automated control of power tightening ensures highly accurate makeup and instant reversal from makeup to breakout. The strength of the system is the robust design, the accurate movement in both torque application and measurement. Furthermore it is easy to use; hence it is able to suit all customer requirements. Another advantage is, that two sets of jaws cover the ultra wide range of serving diameters. Also, special kinds of die inserts are available on request at Weatherford. Aluminum, brass or form shaped dies maintain surface integrity of critical tool surfaces. Special soft-touch dies thus even allow non-marking make-up of chrome tubes. The rotary head is equipped with a 5-jaw gripping system. The gripping force is continuously adjustable according to pipe and coupling materials (high alloy steels or special materials). The main drive of the rotary head consists of two (2) or four (4) hydraulic motors to achieve high torques (and high speeds. The hydraulic backup tong system incorporates a patented design for the virtual compensation of bending and shearing forces when making up or breaking out a tubular connection. Its design allows flexible movement and reduces the possibility of erroneous torque turn readings. The free-floating backup tong practically eliminates alignment problems during the thread engagement and minimizes galling by reducing contact loads.

The ComCAM is available in different machine frame lengths. The short frame version is also combinable with a height leveling system to meet special production requirements. Further components of the Comfort Bucking System are the electric hydraulic power unit to drive the hydraulically operated elements and a control panel with integrated Windows based TPC (Torque Process Controller).

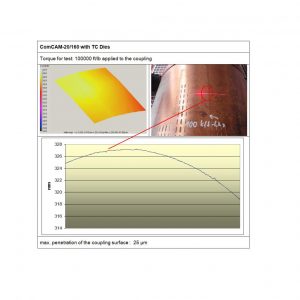

The WEATHERFORD Comfort Bucking System – Model ComCAM-15/160-H (Comfort Coupling Application Machine – 15-inch/160 000 ft-lb – Hydraulic) is designed exclusively for making up or breaking out couplings or completions from 1 to 15-inch in diameter (depending on the used jaw assemblies) during a single shift operation per day. It is capable of generating torque up to 160 000 ft-lb/216 931 Nm in either makeup or breakout mode (only for pipe sizes ≥ 12-inch and a clamping pressure of 320 bar). Performance test of “TC-Grip” Dies (Tungsten Carbide Coating) for CRA tubular

Options

1. Machine Frame Extension to 20 ft (6.100 m)

2.Non Marking Clamping Elements for CRA goods

3.Torque Process Control System (Control Panel)

4.Air Conditioning System for Control Panel

5.Heating Device for the Hydraulic Power Unit

6.Cooling Device for the Hydraulic Power Unit

7.Hydraulic driven Support for the moveable Head- or Tailstock (Chain System)

8.Support Roller (hydraulically operated)

9.Centering Jack ( hydraulically operated)

10.Anti-Slippage Frame Cover

11.Oil Catcher Device

12.Push-Pull Unit

13.External Frame Extensions (different length)

14.Pipe Conveyor System

15.Excentric Clamping Device

Features, Advantages and Benefits

1.Rotational makeup and breakout of couplings and completions

2.Comfortable wide range and step-less gripping range

3.Torque capacity (up to 200.000 ft-lb)

4.Precise torque measuring, controlling and recording using TPCPro torque computer

5.Safe and ease of handling due to operation via control stick

6.Long operation live clamping cylinder design

7.Non-ferrous AluGrip/TC inserts available for CRA tubular makeups

8. Various optional modules available to tailor suit the machine to your application

Related products

-

Bucking Units & Inflatable Thread Protectors

Weatherford TorkWizard 15-150 TL Horizontal Makeup/Breakout Unit

-

Bucking Units & Inflatable Thread Protectors

Weatherford TC Soft Touch Dies for ComCAM Bucking Machines

-

Bucking Units & Inflatable Thread Protectors

Weatherford AL Soft Touch Dies for ComCAM Bucking Machines

-

Bucking Units & Inflatable Thread Protectors

Weatherford Klepo Inflatable Thread Protector

-

Bucking Units & Inflatable Thread Protectors

Weatherford TorkWrench 10-100 HMBU Mobile Bucking Unit