Weatherford TorkWizard 15-150 TL Horizontal Makeup/Breakout Unit

Weatherford’s patented TorkWizard 15-150 TL is a universal horizontal makeup and breakout unit that applies accurate torque for makeup and breakout operations and enables top-loading of drill string components. The TorkWizard unit can be used in the workshop or on the rig for virtually all oilfield connections; for example, drill string components, tools, packers, couplings, and valves.

The TorkWizard 15-150 TL is easy to use in both torque application and measurement. The unit is installed on a machine frame that includes a passive stationary backup device (tailstock) and an active moveable wrenching tong device (headstock). The headstock and tailstock devices have three hydraulically driven clamping cylinders that drive the jaws in and out with an integrated pressure accumulator to provide constant gripping force. The headstock also has two powerful hydraulic wrenching cylinders to turn the swivel head in 30° intervals.

Applications:

• Making or breaking most oilfield connections in shop or rig environments

• Transmitting torque and accurate measurement on drill strings

• Optional making or breaking connections in potentially explosive atmospheres (ATEX certified)

Features, Advantages and Benefits:

• The unique moveable cylinder housing enables higher makeup torques without the risk of bent piston

rods.

• The cylinder is mounted with just two nuts, enabling quick and easy maintenance and repair.

• The gripping system is designed with “upside down” clamping cylinders to prevent damage to the rods.

• The pressure accumulators inside the clamping cylinder ensure a constant gripping force and stability

during the entire clamping process.

• One set of jaw assemblies covers an ultrawide gripping range from 3-1/2 to 15 in. (89 to 381 mm),

without changing jaws or dies.

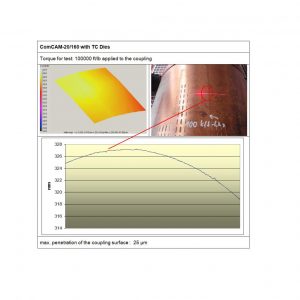

• The automatic clamping pressure booster minimizes die penetration and prevents deformation of the

coupling.

• The unit improves performance and requires less maintenance during the makeup and breakout process,

saving rig time.

• The electronic load cell and torque gauge achieve accurate measurement values at all torque levels.

Specifications:

Technical Data TorkWizard™ 15-150

Maximum ambient temperature range (°F/°C): –4° to +104° / –20° to +40°

Recommended ambient temperature range (°F/°C): +32° to 104° / 0° to +40°

Gripping range (in./mm): 3-1/2 to 15 / 89 to 381

Maximum passing OD (in./mm): 15-1/8 / 384

Maximum makeup/breakout torque at 15 in. (ft-lb, N•m): 150,000 / 203,373

Torque application angle: 30°

Maximum spinner speed during spin-in (rpm): 50

Average sound power level¹ (dB)(A): <80

Approximate weight (lb/kg): 25,574 / 11,600

Overall length, including extensions (in./mm): 924 / 23,470

Width (in./mm): 74 / 1,880

Height (in./mm): 91 / 2,311

Pipe center height (in./mm): 67 / 1,701

Platform length (in./mm): 269.3 / 6,840

Maximum distance between headstock and tailstock (ft/mm): 15.4 / 4,694

Minimum distance between headstock and tailstock dies (in./mm): 3.5 / 88.9

Maximum headstock/tailstock clamping pressure (psi/bar): 8,702 / 600

Maximum headstock wrenching pressure (psi/bar): 3,626 / 250

Hydraulic pressure (psi/bar): 4,061 / 280

Hydraulic flow (gpm, L/min): 24 / 90

Related products

-

Bucking Units & Inflatable Thread Protectors

Weatherford Klepo Special HDH Inflatable Thread Protector

-

Bucking Units & Inflatable Thread Protectors

Weatherford Klepo Special HD Inflatable Thread Protector

-

Bucking Units & Inflatable Thread Protectors

Weatherford TC Soft Touch Dies for ComCAM Bucking Machines

-

Bucking Units & Inflatable Thread Protectors

Weatherford Com CAM15-160 Bucking Unit

-

Bucking Units & Inflatable Thread Protectors

Weatherford TorkWrench 10-100 HMBU Mobile Bucking Unit